SOLUTION

WEB / Mobile

DCM (Demand Chain Management)

DCM is a demand network management system that performs orders/returns/collections/performance of wholesalers, salespeople, and consignment vendors.

-

Wholesale DCM

(Demand Chain Management)

Wholesaler Order/Return Management and Wholesale

-

Sales DCM

(Sales Management System)

Support salespeople, such as direct payment (hospitals, clinics/pharmaceuticals) orders/returns

-

Consigned DCM

(Partner Relationship Management)

Supports business activities of consignment vendors

Major features

-

Order/Refund

Order/return registration, order/return status check, collateral status check

-

Order management

Order management functions (item management, point of sale management, payment line management, Manage Shipping Plates)

-

Payment collect management

Collection processing (virtual account, card payment), collection statement inquiry, collection management

-

Client management

Ability to create, modify, and manage new accounts

-

Performance

Performance registration, performance statistics, and management features salespeople and consignors

-

Wholesale data

Wholesale sales, inventory data retrieval function

-

Sales status

Various sales data inquiry (customer, transaction statement, daily, Monthly sales status)

-

Sales Support

Support for handling travel expenses, daily expenses, and organizational expenses for salespeople

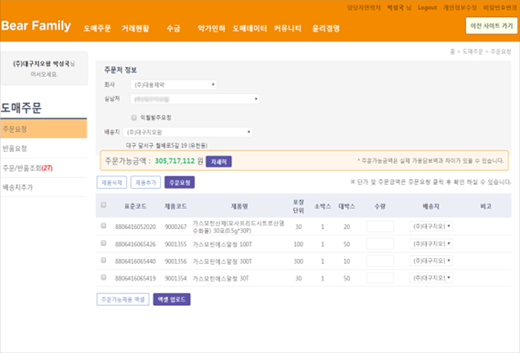

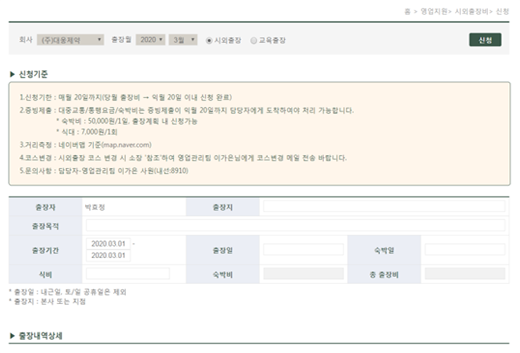

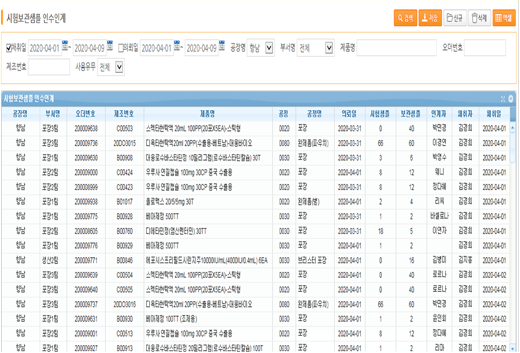

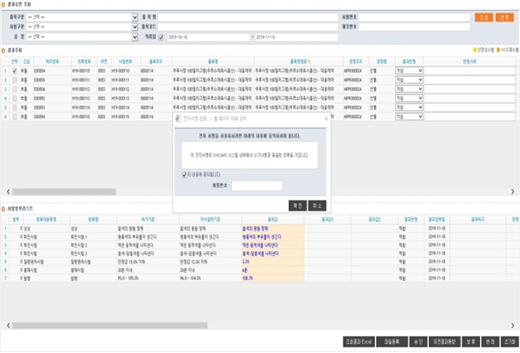

Features 1

SAP-based easy ordering system

It provides a simple web UI that allows users to easily order. It also offers a variety of SAP-based order management capabilities.

-

DCM Main Culture Plane for Wholesale

-

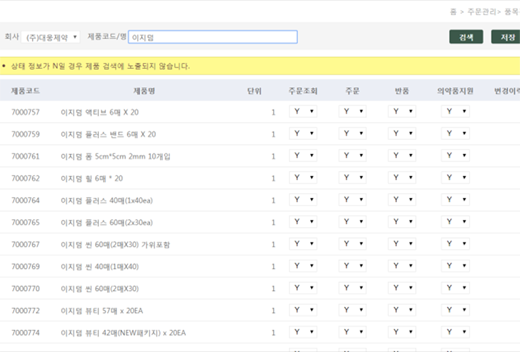

Sales DCM Item Management

Features 2

Provides UX-based convenience for Web & Mobile Support

We've made it possible to work anywhere, increasing efficiency. We also maximized convenience with a webUX base that is familiar to all users.

-

Wholesale DCM Mobile Main/Main Culture Area

-

Salesperson DCM Mobile Main Screen

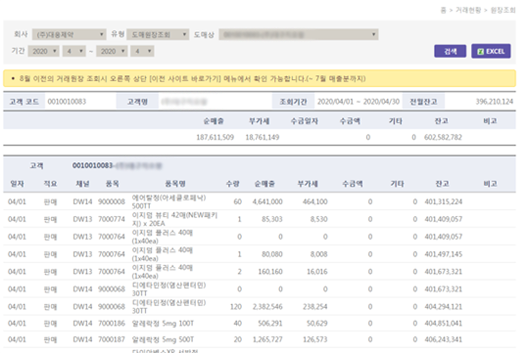

Features 3

SAP real-time revenue analysis

You can inquire the sales data of the ledger and statement in real time.

Helps you create an efficient marketing strategy with aggregated statistical capabilities.

-

Consolidated DCM Transaction Statement

-

Salesperson DCM transaction statement

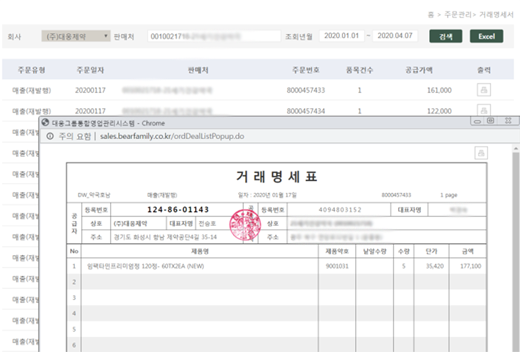

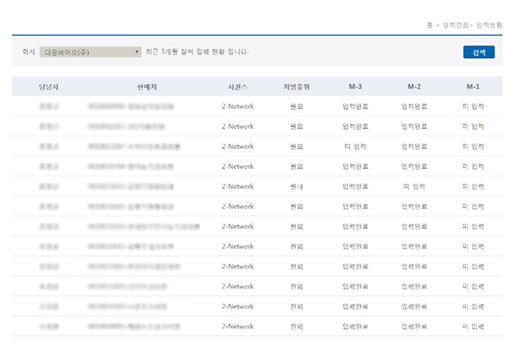

Features 4

Provide sales management system

Provides business support and management functions such as ordering, performance, and handling of unproven expenses for salespeople.

-

Salesperson DCM travel expenses

-

Salesperson DCM performance

-

consigned DCM performance input status

-

Subcontracting DCM Account Application

POP (Point Of Product)

Point of Product (POP) is a system necessary for sharing information and stabilizing quality and improving productivity through the control of process production progress and facility management by real-time management of information generated during manufacturing and production.

Major Features

-

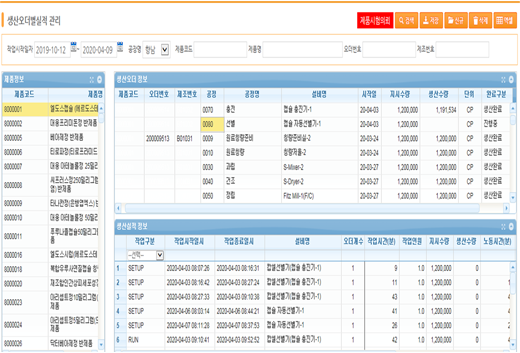

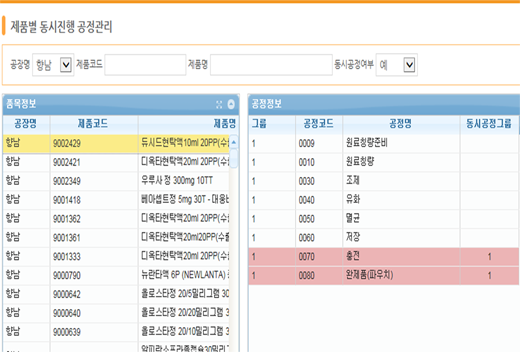

Production order

Production/Virtual Order Management, SPLIT, Simultaneous Process Management

-

Production performance

Production/virtual order preparation/operating/cleaning and non-operating performance/manual real-time management

-

Supply management

Management of production orders and other orders, virtual orders, and absenteeism and tardiness management

-

Various numbers

Provide various indicators such as production progress, load analysis, lead time, yield, worker analysis, etc.

-

Outside system sync

SAP, BI, TMMS sync

-

Interface monitoring

Real-time external system interlocking results check and reprocess

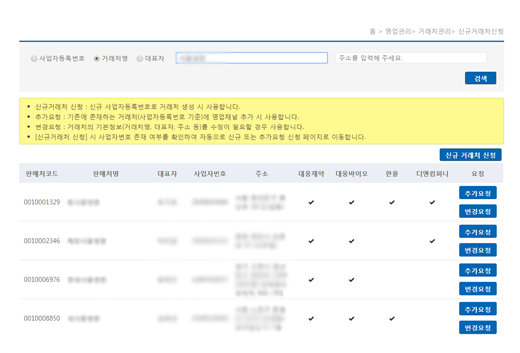

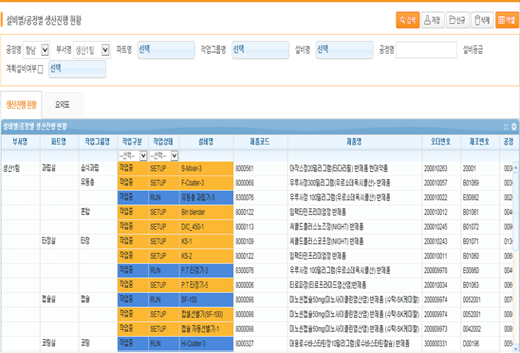

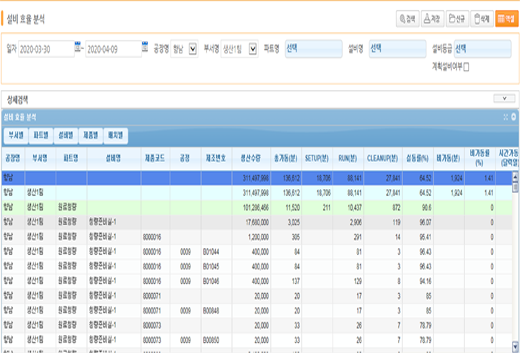

Features 1

Provide real-time information by production process stage

Provides real-time on-site monitoring.

Facility non-operation analysis and response are possible.

-

Production Order Information

-

Production progress status by facility/process

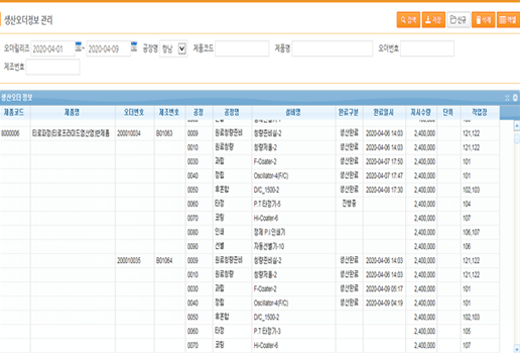

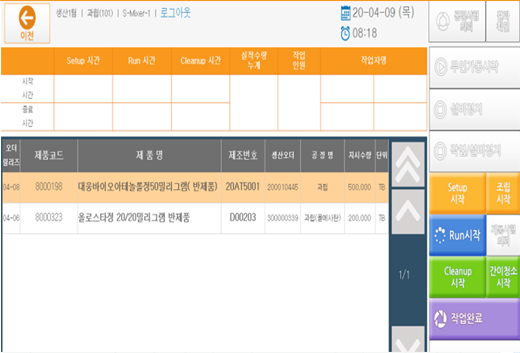

Features 2

Support accurate production planning and purchase management by reflecting SAP real-time field information

Provides a web UI that allows easy monitoring real-time production order and input of production performance.

Also provides SAP I/F real-time monitoring and reprocessing.

-

Site - Check Order and Register Performance (Real-time Reflection)

-

Performance management by production order

Features 3

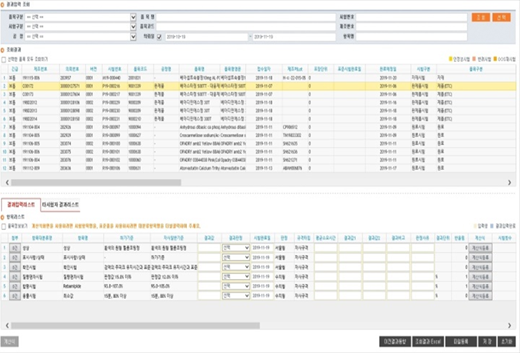

Bidirectional interworking of LIMS through inspection request

Provides inspection, product inspection request, and decision results during the process.

Easy UI is provided for inspection requests.

-

Requesting an inspection during the process/checking the results

-

Current status of transfer of test storage sample

Features 4

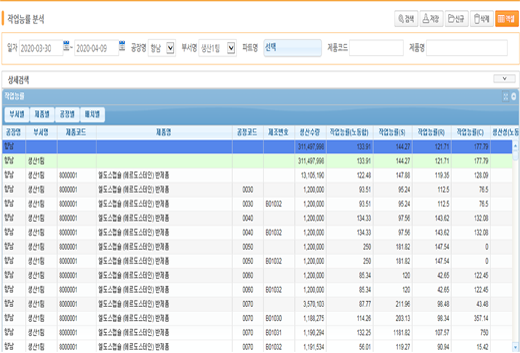

Provide a variety of indicators to help identify trends and make decisions.

Provides more than 20 indicators including production progress, load analysis, lead time, yield, and worker analysis.

Also provides real-time, expanded report raw data with SAP BI interworking.

-

Facility Efficiency Analysis

-

Operational Efficiency Analysis

Features 5

Functions for convenience and Performance Accuracy ↑

When entering performance, break time is managed so that work can be done conveniently without any additional shutdown.

In addition, enables convenient input of performance through simultaneous process management.

-

break time management

-

Simultaneous Process Management

LIMS(Laboratory Information Management System)

Computer system designed to manage various data generated in the laboratory and support Lifecycle of data including data collection, storage, analysis, reporting, and storage.

-

LIMS/ LES

( Laboratory Information Management System

Laboratory Execution System )Laboratory Information Management System

-

SDMS

(Scientific Data Management System)

Scientific Data Management System

-

LAS

(Laboratory Automation System)

Laboratory Automation System

Major features

-

Test

Processing test procedures (test reception, sample collection, test order, assignment of test subjects, input of results, review of results, final approval)

-

Test planning

Register and manage plans for stability testing and calibration/qualification assessment plans

-

Resources management

Manage the use and disposal of stored samples, stability samples, and the history of device use.

-

Reagent/Standard Product Management

Control the history of labelling, opening, disposing and using reagents and standard products used in testing

-

Settings management

Site-wide management with information processing on passwords, outputs, and Audit Trail

-

Master

Overall basic information management such as users, items, and specifications

-

SDMS

Feature to collect, classify, reuse, and manage data

-

LAS

Data Extraction Method Settings and Type-Specific Data Extraction Capabilities

Features 1

Test Process Management and Business Standardization

Systematized management of laboratory data input errors and laboratory business processes provides the ability to comply with U.S. FDA, GMP, and domestic and international legal regulations and ensure adequate quality.

-

LIMS - Enter results

-

LIMS - electronic signature

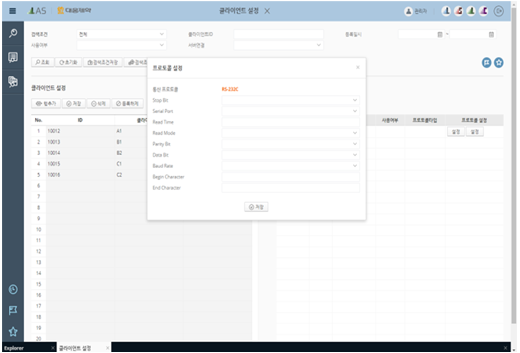

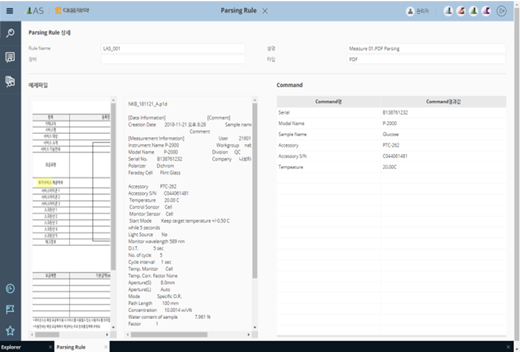

Features 2

Automated test device data collection

It provides the ability to automatically process data transfer to other systems by collecting, storing, and processing data in conjunction with test devices.

-

LAS-Client

-

LAS-ParsingRule

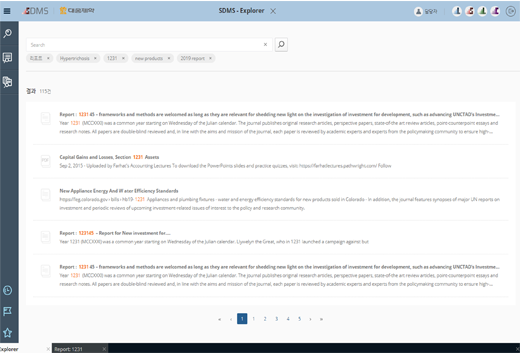

Features 3

Laboratory Data Management

Documenting lab-generated raw data for safe storage, management, and utilization helps improve FDA's Guidance for Data Integrity compliance and work flow.

-

SDMS-Explorer

-

SDMS-Preview